Keyboard Shortcuts

Likes

- 7x12MiniLathe

- Messages

Search

|

Re: An Extra Leadscrew

开云体育??? Interesting . I was able to get to that Clocks magazine article , so I have some reading to do . I could see a 3D printer come in handy for making index plates with the proper amount of teeth I then using one of the prints on the indexing side of the mini lathe . WHen I first got back in to machining? I spent way way toomuch

time following a few clockmaker quys on youtube & was so

amazed whth what thm guys could pull of with those almost mirco

lathes . I kinda kick my self , many years back I was offered I think it was a Lorch, but it coud have been a Levin watch makers lathe with a ka-zillion collets& other attachments for $ 200.00 , & I turned that offer down . then years later I was at a yard sale & bought my first MIll , a Harbor Freight Big Red mill/drill . I put a bunch of other things I wanted in a pile & told the guy to give me his best price . We went back & fourth a couple times & finally he? gave me his last # & I remember that there was a real small lathe on one of the benches & I told him , Ok I'll do that price but ya have to toss in the little home made lathe & help me load the mill in my truck . He was pretty tired of messing with me & agreed So we loaded everything in my truck & I left . a few days later I found out that that home made lathe was actually a Taig lathe with just about every attachment they had except for the leadscrew & some collets .

I have used that Taig a bunch since then & really enjoy

making small parts with it . It's between a Mini lathe & a

actual Watch makers? lathe .

sorry for the long winded reply , but there isn't much other stuff going on here . thanks for the link animal

On 5/11/25 7:21 PM, Johannes wrote:

|

|

Re: An Extra Leadscrew

开云体育

Mike

"SO I'm guessin that ya have a stop of some kind so ya don't cut too deep with the gear cutter? ?"

If I understand your question correct,? this is my way to cut a clock wheel:

A clock wheel has shape. It is called Epicycloidal. Full of mathematic and practical experience.

The main reason is to reduce friction to pinion to be as little as possible. Very little oil is used in a clock.

The tooth top can have a tip.

So before cutting I paint the surface, and when the tip is only a small line. I know the depth is correct.

Johannes

Mexico

From: [email protected] <[email protected]> on behalf of mike allen <animal@...>

Sent: Sunday, May 11, 2025 14:23 To: [email protected] <[email protected]>; Clocksmiths <[email protected]> Subject: Re: [7x12MiniLathe] An Extra Leadscrew ?

thanks , I totally missed the wheel in the earlier pic , I ws too busy checkin out the gear cutting setup . I've seen folks also use saw blade's , if ya can find one with the tooth count? needed . thanks for sharing . SO I'm guessin that ya have a stop of some kind so ya don't cut too deep with the gear cutter? ? thanks animal On 5/11/25 1:37 PM, Johannes wrote:

|

|

Re: An Extra Leadscrew

开云体育thanks , I totally missed the wheel in the earlier pic , I ws too busy checkin out the gear cutting setup . I've seen folks also use saw blade's , if ya can find one with the tooth count? needed . thanks for sharing . SO I'm guessin that ya have a stop of some kind so ya don't cut too deep with the gear cutter? ? thanks animal On 5/11/25 1:37 PM, Johannes wrote:

|

|

Re: An Extra Leadscrew

开云体育

Hi Mike

As you have seen on the other pictures (hopefully), there is a big wheel on the left side of the lathe, fastened to the spindle.

My wheel has a circumflex of 1502 mm, however the distance between the millimeter marks is also a mark, so I have 3004 "marks" . My eyes are not as they were, so I have put on a magnetifying glass.

So, if you are standing on the same foot, in the same position and use the same eye, you can get a good reading.

With the Excel program, it is easy to do the calculation. My reading of hundred is 0 or 5.

Ex.? 91,35?

On the picture you can see a thin red needle. If you put the 2 needles in line, it will be easier to do a good reading .

The relation between reading wheel and clock wheel is around 10:1.

However, it happens I have to make a new clock wheel.

/Johannes

Mexico

From: [email protected] <[email protected]> on behalf of mike allen <animal@...>

Sent: Sunday, May 11, 2025 12:46 To: [email protected] <[email protected]> Subject: Re: [7x12MiniLathe] An Extra Leadscrew ?

??? ??? Thats pretty slick., how are ya keeping track on the indexing when ya gut? gears ? Is there something on the other side of the spindle that locks in position ? thanks On 5/11/25 8:44 AM, Johannes wrote:

|

|

Re: An Extra Leadscrew

开云体育??? ??? Thats pretty slick., how are ya keeping track on the indexing when ya gut? gears ? Is there something on the other side of the spindle that locks in position ? thanks On 5/11/25 8:44 AM, Johannes wrote:

|

|

Re: An Extra Leadscrew

开云体育

Hi

The nut is fastened on a little plate on the back side of the saddle.

The motor is a very cheap , higher speed water pump motor. Silent and strong enough for the job.

As you can see, I have replaced the original press board with a brass plate, it is longer and has an extra contact pressure on the outside of the bed-way. This is done on the back side also. This gave me a much better anti-twist of the saddle.

This new lead screw is easy to set up with 2 screws for special jobs. To cut a clock wheel with 144 teeth takes time.?

One tooth wrong, you have to start again.

Good advice: Start with the biggest "wheel" first.

Johannes

Mexico

? ? ? ?

?

From: [email protected] <[email protected]> on behalf of mike allen <animal@...>

Sent: Saturday, May 10, 2025 23:55 To: [email protected] <[email protected]> Subject: Re: [7x12MiniLathe] An Extra Leadscrew ?

Nice job ! I'm guessin that theres a nut under the carriage/saddle somewhere . What motor are ya usin now for the spindle ? thanks animal On 5/10/25 9:24 PM, Johannes wrote:

|

|

Re: An Extra Leadscrew

开云体育Nice job ! I'm guessin that theres a nut under the carriage/saddle somewhere . What motor are ya usin now for the spindle ? thanks animal On 5/10/25 9:24 PM, Johannes wrote:

|

|

An Extra Leadscrew

开云体育

This is my last improvement to my 7x16:?

a 500 mm CNC T8 Leadscrew inside the bed-way, with a hand-crank outside.

My previous improvement in same subject was a hand-crank connected to original lead screw.

With this hand-crank the cutting is improved very much comparing to use the original hand wheel.

?

I am cutting clock wheels, so when I have cut one tooth, and have to return the cutter back for the next tooth, it has to be exactly same position, otherwise the tooth will be smaller. 0,1 mm is very visible.

Johannes

Mexico

?

|

|

Group Guidelines

#guidelines-notice

Group Notification

TERMS OF USE -- How the 7x12 Group Operates

The 7x12 Minilathe forum was founded as a way for machinists, both expert and novice, to help each other learn about our machines and to inspire each other to try new things. Here you can ask machining questions and expect to get knowledgeable answers. You can ask for help in finding just the right technique or design for a particular project. The files and archives can be searched for helpful hints and ideas to improve your knowledge and the quality of your work. In return we ask that you confine your discussions to machining related topics,? that you treat each other as you would want to be treated, that you write your messages with a sense of camaraderie, and that you honor the rights of those who willingly give of their time by sharing their knowledge and ideas with you. Over time a group personality emerges, shaped by the people and personalities who comprise the group.? We would like this group to be friendly and welcoming, a place where machinists of all skill levels come to teach and to learn and we ask your cooperation in meeting these goals. To help achieve those goals, the following rules govern operation of this group: ? * On-Topic posts only. Posts are not normally moderated, except those from relatively new members. But posts which are clearly off-topic will be deleted; ? the member's email status may be changed plus their posting status may be changed so their future messages are moderated.? To avoid this, please refrain from responding to OT posts. Leave decisions as to whether a subject is OT to the moderators. Give them a little time to deal with? the matter, and some latitude in judging what is off-topic. ? Experience has shown that some topics can drift into off-topic areas; for example,? posts about using a lathe to make angling equipment can degenerate into fishing? reminiscences and those about making car parts into the merits of member's past vehicles. Posts on making gun parts are a particular problem, as they can end up as general discussions about firearms and ballistics, or worse still as sterile arguments about the merits or demerits of gun control, where no-one is ever likely to persuade anyone else to change their views. ??? Think before you post? - is what you will be saying really on the subject of lathes and machining? * CNC, ELS and 3D Printer topics are handled in the /g/digitalhobbyist? which is dedicated to these and similar topics. Or, /g/3D-Printing-for-Metal-Hobbyists * Please avoid religious or political asides or references in your messages, and likewise quotations, slogans etc at the end of them.? Limit signatures to 2 lines maximum. ? * Be civil to your fellow members; derogatory or combatively worded posts will be deleted, and offenders placed on moderation. * Pictures: Following our move to Groups.io we would like to allow members to post pictures. ? We ask that only machining related pictures of lasting interest be posted. When appropriate include mention of the message number concerning the topic covered in the picture(s). ? Members who expect to post a number? of pictures should make an album containing their name to hold their pictures.?? ? Pictures of passing interest should be posted in messages or on public servers like Flickr. * Files: Members may post machining related files.? Again, these should be of lasting interest. * LINKS are found in the left menu of the Forum under Databases. Moderators may remove pictures or files judged not to meet the above stated criteria. ?Moderators are currently:? John = GadgetBuilder = John@... Mike = DrMico60 Trevor = Trevor_Rymell? Maximum size of pictures should be 800x600. Pictures may be cropped and/or resized using Irfanview (free) or any other photo processing program. One criterion for inclusion is that the photo should be of lasting interest, like a lathe modification or accessory, rather than something which will only be of interest while a question is being asked about it. This avoids "Photos" getting too cluttered with pictures relating to long-forgotten threads.? ? *** Moderators reserve the right to determine what is and what is not? appropriate for this group as well as the right to delete messages and/or? remove members. This is not up for discussion or debate. *** ? Suggestions to members: ? When quoting previous posts, eliminate non-pertinent text, but keep enough so your response has some context. ? If you want to delete one of your posts: view your message on the forum and then click on the trash can at the bottom. Though you may receive copies of posts in your email, they can only be deleted by visiting the Group. ? Members may post "For Sale" info for their personal lathe or related item but we don't allow advertising by vendors; when posting, ensure your email via the Group is correct so members may contact you. Members wishing more info or wanting to purchase an offered item MUST use email to contact the seller; responses sent via the group will be deleted. ? Members may use the group to connect with other members when they need machining done that they cannot do themselves. Responses and further refinement of details should be done via email rather than by posting to the group. See "Helping Hands" in the Files section for 7x12 Group members who will machine items for others at reasonable cost. ? New members please look at the files (especially FAQminilathe) and Search the archive for answers to common questions. ? Thank you for joining! |

|

Re: Mysterious Starrett tools. What are they for?

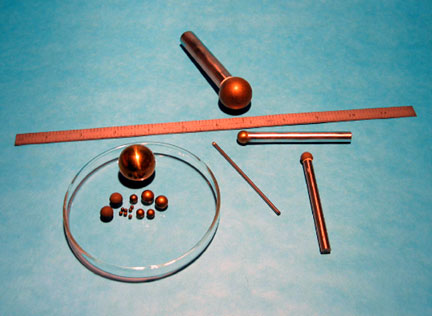

'Tooling balls" are usually used as part of making setups by creating referencing points. Tooling balls have a precision ground shank.??What Mike has is not tooling balls because they have knurled handles.? This is for holding them with one hand while you tap them with a hammer.with your other hand. If somebody wants an idea of what tooling balls are, and how they are used, here is a YouTube on it. Charles E. "Chuck" Kinzer

On Wednesday, April 30, 2025 at 05:37:45 PM PDT, Roy via groups.io <roylowenthal@...> wrote:

They look like, "tooling balls."?

?

?

?< >

?

Roy

|

|

Re: [LL] Mysterious Starrett tools. What are they for?

Something used as a lap must be able to "hold" the abrasive in a lapping compound or solution (which can be ludicrously fine diamonds such that the solution just looks like dirty water).? But the "lap" has to hold those particles which is why laps are usually softer metals with the hardest being maybe a nice grey cast iron like meehanite. Charles E. "Chuck" Kinzer

On Tuesday, April 29, 2025 at 10:32:48 PM PDT, mike allen <animal@...> wrote:

perhaps they were used for lapping ball seats ?

animal

On 4/29/25 10:11 PM, Miket_NYC via

groups.io wrote:

I bought these recently in a thrift store in New

Hampshire where I've bought many tools. They're made by Starrett

and each consists of a ball on the end of a knurled shaft.?

The balls are very precise. The small one is 1

1/2 thousandths

smaller than 0.5" (an amount that could easily have been lost over the decades). But the small ends of both shafts are swollen and scarred from pounding, so these were apparently intended to be pounded into something with hammers. I have both a modern Starrett catalog and a 1936

catalog, and I don't see these listed,? either under measuring

tools or punches and similar things intended to be hit with

hammers. Also, they don't have part numbers, like most small

Starrett tools.

Initially, I thought a previous owner might have

welded or brazed the balls onto Starrett punches or something

like that, but that's apparently not true. It's clear, at

least on the large ball, that each ball and shaft is turned

from one piece of metal.

Any ideas? These gizmos were so cheap that I

couldn't pass them up, but I'm flummoxed about what they are

and what they could have been intended to be used for.

Mike Taglieri?

|

|

Re: Mysterious Starrett tools. What are they for?

They look like dapping punches to me.? These are typically used with a mating block with an assortment of different sized recesses.? You can make little dome shapes in sheet metal. What I have used them for is to make a hole in sheet metal a little smaller.? This may not be the intended purpose, but it works if you have a hole that is just a little oversize.? You back up the sheet metal on a solid flat surface, center a dapper punch that is much larger than the hole, and give it a hit or two with a hammer.? This compresses the metal a little and, with nowhere to go except to the interior of the hole, the hole shrinks a little. Charles E. "Chuck" Kinzer

On Tuesday, April 29, 2025 at 10:12:05 PM PDT, Miket_NYC via groups.io <mctaglieri@...> wrote:

I bought these recently in a thrift store in New Hampshire where I've bought many tools. They're made by Starrett and each consists of a ball on the end of a knurled shaft.?

The balls are very precise. The small one is 1 1/2 thousandths smaller than 0.5" (an amount that could easily have been lost over the decades). But the small ends of both shafts are swollen and scarred from pounding, so these were apparently intended to be pounded into something with hammers. I have both a modern Starrett catalog and a 1936 catalog, and I don't see these listed,? either under measuring tools or punches and similar things intended to be hit with hammers. Also, they don't have part numbers, like most small Starrett tools. Initially, I thought a previous owner might have welded or brazed the balls onto Starrett punches or something like that, but that's apparently not true. It's clear, at least on the large ball, that each ball and shaft is turned from one piece of metal. Any ideas? These gizmos were so cheap that I couldn't pass them up, but I'm flummoxed about what they are and what they could have been intended to be used for. Mike Taglieri? |

|

Re: [LL] Mysterious Starrett tools. What are they for?

开云体育perhaps they were used for lapping ball seats ?

animal

On 4/29/25 10:11 PM, Miket_NYC via

groups.io wrote:

|

|

Mysterious Starrett tools. What are they for?

I bought these recently in a thrift store in New Hampshire where I've bought many tools. They're made by Starrett and each consists of a ball on the end of a knurled shaft.? The balls are very precise. The small one is 1 1/2 thousandths smaller than 0.5" (an amount that could easily have been lost over the decades). But the small ends of both shafts are swollen and scarred from pounding, so these were apparently intended to be pounded into something with hammers. I have both a modern Starrett catalog and a 1936 catalog, and I don't see these listed,? either under measuring tools or punches and similar things intended to be hit with hammers. Also, they don't have part numbers, like most small Starrett tools. Initially, I thought a previous owner might have welded or brazed the balls onto Starrett punches or something like that, but that's apparently not true. It's clear, at least on the large ball, that each ball and shaft is turned from one piece of metal. Any ideas? These gizmos were so cheap that I couldn't pass them up, but I'm flummoxed about what they are and what they could have been intended to be used for. Mike Taglieri? |

|

Re: Parting Off

Apologies for pressing some buttons, and sending everyone off in a tangent. Al was supposed to mean Aluminium or Aluminum of course. Lets redirect with parting thoughts.

--

Evan Lathe: 1955 Boxford Model A with screw cutting gearbox, power feed with several accessories, hand tools and a pillar drill press. Try my Free Online Gear train Software: You enter a thread pitch or TPI and it shows you a range of gear trains and gearbox setting to use and even a scale drawing of the gear train. It also includes calculations for taper turning by the tailstock offset method, and cutting speeds. It includes the specifications for many thread types eg metric, UNC, BSW, and BA. Displays drill sizes for tapping threads at any percent thread depth (with full explanations). My YouTube Channel and Playlist about using an engineers lathe: ? Project to build a Greek Hero steam engine and measure its power output:? |

|

Re: Parting Off

开云体育Dear machinists, On 29.04.25 14:22, WAM via groups.io

wrote:

You didn't read the link.? Read my ChatGPT transcript where even it states it's not intelligence.?... |

|

Re: Parting Off

You didn't read the link.? Read my ChatGPT transcript where even it states it's not intelligence.

toggle quoted message

Show quoted text

AI has been here since the Perceptron in the 50's. But the first AI winter occurred when the hippies figured out it was all hype. And then they went on to prove entanglement via? Bell's Inequality in favor of Bohr over Einstein. Smart bunch. I design that hardware.? Just finished a PCB last week with an NVIDIA ORIN,? It's not intelligent. Really read that first link.? I work with too many professors that agree - not intelligence. As Prof Jones at Princeton states: "Big part of what I've been working on has? been the rather remarkable rebranding of linear algebra and ml as AI. "? LLM's are an extension of what we used to call expert systems. Just that now any idiot can use them. All it is... The NVIDIA CEO is starting to act like Dr. No from that Bond flick. Bitcoin mining went away; gotta do something to sell those math engines. One client I have actually met him, and it's been two years and NVIDIA's crew is still trying to get the stuff to work like they promised. Naw man, it's a lot of BS...marketturds if you will. As to engineering, machining, etc.. it can be very helpful as an expert system.? But it'll never have the creativity of a skilled machinist or engineer. Just a parrot... We're getting off topic here...? anyone got any cool mods to their lathe? On 4/29/2025 3:12 AM, Tony Smith via groups.io wrote:

Man, that's some "old man yells at cloud" energy. Abe Simpson would be proud. |

|

Re: Parting Off

开云体育Hi Tony et al. ? As usual, 50% of anything new is excellent and 50% is absolute dangerous rubbish. ? The trick is knowing which 50% is which !!! ? ????????????????? Ellis ? ? ? Man, that's some "old man yells at cloud" energy.? Abe Simpson would be proud. ? C'mon, you've seen this before.? New tech over-hyped by its creators, with the "we'll all be doomed!" crowd yelling in the background.? It'll be brain implants or cyborgs in another decade. ? It happened for the internet (remember that fad?), computers, mobile phones, point-of-sale machines, TV, calculators, radio, books and probably even paper (if stone is good enough for God, it's good enough for the rest of us!). ? While I don't disagree with you, like everything else AI is here to stay.? So what if it's wrong, so is everything else. ? Yeah it’ll make the kids stoopid, so did everything else. ?Especially jazz music. ? But what if it stops working you say?? Well, we said that about everything else as well.? Imagine installing electronic cash registers and the power goes out!? How will I pay?? We'll all be doomed! ? But what about AI slop?? Well, as writer Theodore Sturgeon replied when asked if 90% of science fiction was crud, replied with "Sure, but 90% of everything is crud." ? AI is just another tool.? Like all tools it has its uses.? I save stuff I find interesting, and on my PC a folder eventually had about 40,000 pictures in it.? Of course I put them in subfolders, like clocks, boxes, etc.? But I rarely renamed them, so most of them were called something like ergv45yb34tb3q4.jpg ? Anyway, one day I fired up Google Gemini and set it loose on that folder.? And it did a really good of identifying and renaming those images.? Some were incredibly spot-on, like this: ? ? “Alice in Wonderland Playing Card and Tea Party Silhouettes on a Purple Textured Background.jpg” ? I mean yeah, that’s what it is. ? It was kinda fascinating watching it work it way thru the images.? Some names were funny, some were wrong, most were rather bland ("a cat cut out of wood") but better than what I had.? At least now I could search for "cat" and find something. ? As an aside go here: and download "Everything".? It will index your PC and instantly find anything.? It's very good.? You can also set your own filters, eg I added one called "Vectors - ext:ai;cdr;dwg;dxf;svg" that returns files with those extensions. ? I'll leave you to complain about them damn kids not learning cursive handwriting anymore (or any handwriting really), and toss in this as well: ? Tony |